- At 02-12-24 14:11:51

- Announcements

- Zack S

- Read Time: 4 minute read

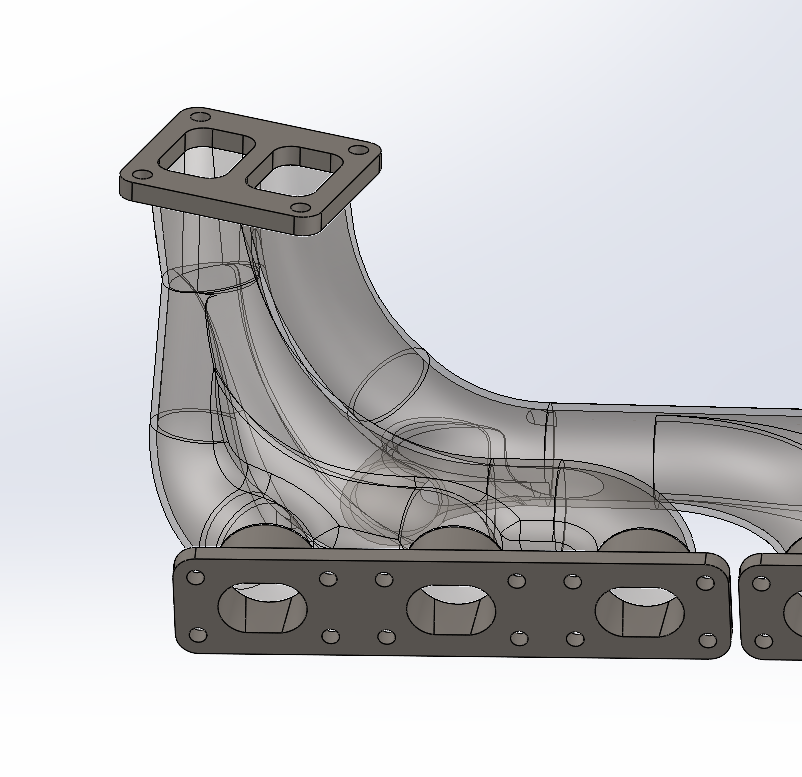

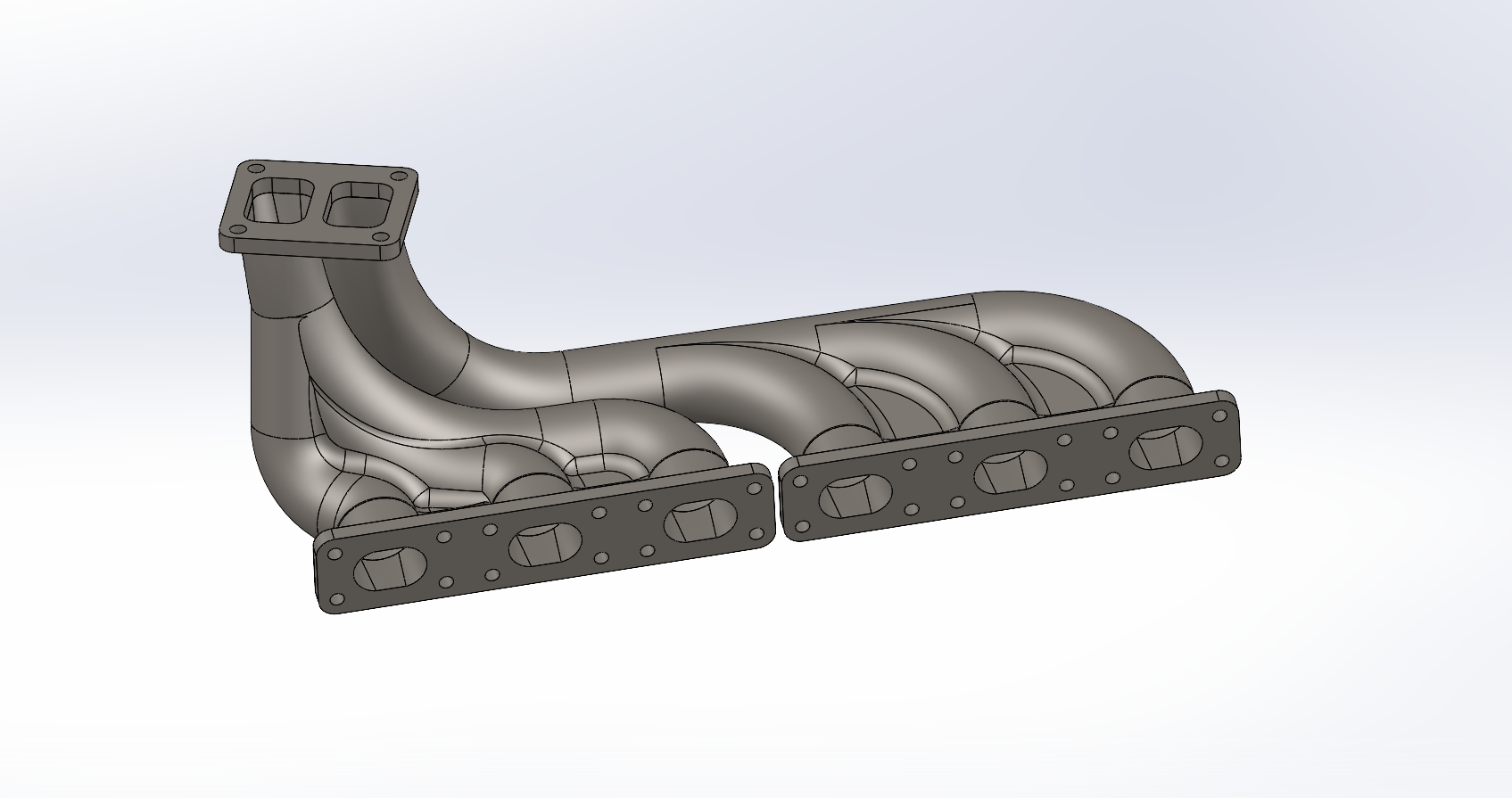

CNC Turbo Manifolds: The Future of 22RPD Manifolds

Unleashing the Full Potential of Your Turbo: The CNC Advantage

In the pursuit of better engine performance, the choice of a turbo exhaust manifold can make a significant difference. At 22RPD, we understand the critical role this component plays in your vehicle's powertrain, and that's why we're excited to dive deep into the benefits of fully CNC machined turbo exhaust manifolds. Unlike traditional cast or welded tubular manifolds, CNC technology offers unparalleled precision, customization, and efficiency, making it the superior choice for those manufacturers who are willing to invest the considerable time and effort to make them a reality. Fortunately, we're already hard at work making this a reality for you.

Customization: Tailored Performance for Every Need

One of the most compelling advantages of a CNC machined turbo manifold is its adaptability. Thanks to the precision and repeatability of CNC machining and Computer aided design (CAD), we can offer design variations tailored to meet specific power goals and setups. This approach ensures that each manifold not only fits perfectly but also optimizes your vehicles power, torque, and spool time.

Our goal is to offer several different manifold designs for each platform, where we can adjust the design for the engine goals and turbo fitments. Cast manifolds can not offer this flexibility because they are limited by the constraints of mold-based production, and therefore are produced as a one-size-fits-all manifold. Tubular manifolds can be adjusted to meet your goals, but welded tubular manifolds are constrained by the limitations of traditional steampipe sizes so you either receive a manifold with too small or too large of a base runner diameter. With CNC we can adjust and iterate a design so its exactly what we want, this is unmatched by any process except perhaps additive manufacturing or "3D-printed" manifolds, which remain prohibitively expensive.

Next we should discuss two other huge Factors in manifold manufacturing: Variability and Quality.

Cast manifolds, where the material is poured into molds, clearly have a material quality concern. Is the density consistent, was the material clean, and since we are relying on gravity to get the liquid into the corners and around the multiple pieces of a mold there can be a huge amount of variability of the quality of the final product. The only real benefit to cast manifolds is cost. In large volumes this manufacturing method can be extremely cheap. But generally we score it as the worst with general process control of variability and quality.

Next, "Tubular" manifolds, constructed from pre-manufactured tubes, exhibit the broadest range in quality and variation. Each manifold produced, even off of a jig, will have differences from the last. While a good fabricator can minimize these variations, it's a time-consuming and costly effort.

This is an easily tested point: How often have we heard of offshore produced headers not fitting? How expensive are locally sourced or custom headers?

We can all agree this process has variation, but what about its quality? There is the potential for a tubular manifold to perform ideally but then you take the design and constrain it to limited pipe diameters and sizes. How confident that these diameters and sizes make for the ideal manifold? Then this design must be iterated by hand to improve it. Even the best fabricators will agree you get what you pay for and manifolds are an extremely time consuming process. But lets say you have the best fabricator and the biggest budget. You are still being limited by this human having to weld several hundred inches perfectly. This is a challenge in the best conditions and let us just say welding a manifold is rarely the best situation.. Often it is about the worst situation in welding. This is exactly why we say the process has huge variation, quality and performance can be there if the power goals, time, budget, and fabricator all line up.

Next lets discuss these points for CNC produced manifolds. The machine will consistently hold tolerances tighter than 0.002 inch, think a fraction of the thickness of your hair, so we know it will produce a product with lower variation than the other two methods above. Next we look at material quality, generally these will be produced from suitable billet material, generally offering superior homogeneity and consistency. Welding is minimized, significantly reducing potential failure points and human error. Freed from the constraints of pipe sizes or molds, we can strategically eliminate non-essential material. Since we are not limited to pipe sizes or molds we can remove material that is not giving a strategic benefit. The interior pathways and volumes are free from weld slag or mold deviations.. At this point you may be asking is there even a downside? Yes, time and startup cost. It is a huge effort to design a manifold that works well and even harder yet to design one that can be machined thereafter. Even if you can do both of these the cost to break into this production method is probably 50-100x the cost of tubular manufacturing methods. Our decade-long experience manufacturing many tubular manifolds informs our move towards CNC, anticipating reductions in production time, costs, and an increase in design quality. We choose not to compromise on quality or involve third parties unnecessarily or casting would be considered.

Conclusion: The CNC Machined Manifold Difference

At 22RPD, we believe in providing our customers with the best performance solutions available. The advantages of CNC machined turbo exhaust manifolds tailored performance, unmatched reliability, precision manufacturing, and lightweight design set them apart as the optimal choice for enthusiasts and professionals alike. Whether you're aiming for peak power, rapid spool times, or unparalleled reliability, the CNC advantage is clear. Follow along as we unlock the true potential of your turbo setup.